Table of Contents

Introduction to CNC Wood Carving

What is CNC wood carving?

CNC wood carving is a new woodworking method. It uses CNC machines to carve, cut, and engrave wood. This technique offers very precise results. These machines make it easier for woodworkers.

They help create detailed designs, 3D carvings, and engravings quickly. This is different from traditional methods that need manual labor.

CNC technology is great for both hobbyists and professional woodworkers. It helps you create wood art, furniture, home décor, and custom projects. CNC routers, carving machines, and engraving tools enable users to work accurately. They are effective on materials like solid wood, plywood, acrylic, and plastic.

How CNC Machines Revolutionized Woodworking

The advent of CNC wood carving machines has transformed the woodworking industry. Before CNC technology, intricate wood carvings required hours of manual labor. CNC routers and engraving machines make it easy for woodworkers to create complex designs. They offer automation and precision, allowing for impressive results with less effort.

Key innovations in CNC technology include:

- 3-axis and 3D CNC machines for enhanced design flexibility.

- Ball screws and rotary features for superior accuracy.

- Laser engraving and CNC milling capabilities for detailed engravings.

- Software like Easel & VCarve to streamline design workflows.

Advantages of CNC Wood Carving Over Traditional Methods

- High Precision: CNC machines eliminate human errors, ensuring flawless engravings and carvings.

- Efficiency: Reduces production time while improving consistency in designs.

- Customization: Perfect for home décor, wall hanging designs, and small business ventures.

- Versatility: Works with wood, acrylic, plastic, and other materials.

- Accessibility: Beginner-friendly DIY CNC machines make wood carving more accessible to everyone.

Key Components of a CNC Wood Carving Machine

CNC Router Machine and Its Functions

A CNC router machine is the backbone of CNC wood carving. It is designed to cut, carve, and engrave materials with high precision and efficiency. These machines are widely used for woodworking projects, 3D modeling, and custom designs.

Many popular models, like the Next Wave Shark, have great features. They include rotary carving, spindle cooling, and emergency stop buttons. These features help ensure safety and accuracy.

Importance of Spindle and Cutting Tools

The spindle is a critical component of any CNC wood carving machine. It determines cutting speed and precision. Using high-quality cutters, router bits, and engraving tools enhances the quality of CNC carvings.

Understanding 3-Axis, 3D, and 4040 CNC Machines

- 3-axis CNC machines move in X, Y, and Z directions, making them ideal for engraving and wood carving milling projects.

- 3D CNC routers provide additional flexibility for complex designs and artistic carvings.

- 4040 CNC routers are compact machines suitable for hobbyists and small business owners.

CNC Milling vs. CNC Carving: What’s the Difference?

- CNC milling is focused on cutting and shaping, which is best for fabrication and industrial applications.

- CNC Carving specializes in detailed artistic engravings, which are perfect for wood art and personalized projects.

Ball Screws and Rotary Features for Precision

The inclusion of ball screws in CNC machines ensures smooth movement and minimal backlash. Rotary features enable cylindrical carving. This makes it easy to engrave furniture legs, sculptures, and detailed home décor items.

Precision in CNC Wood Carving

High Precision and Intricate Designs

CNC machines offer great precision. This helps woodworkers make detailed designs over and over. Features like spindles, ball screws, and rotary capabilities contribute to better accuracy.

How to Achieve the Best Engraving and Cutting Accuracy

- Use high-quality STL files for accurate design execution.

- Calibrate the work area to prevent alignment errors.

- Choose the correct spindle speed based on the material (solid wood, plastic, or acrylic).

Impact of Software Like Easel & VCarve on Precision

Design software, like Easel and VCarve, makes CNC wood carving easier. It offers pre-set templates, shows carving previews, and gives you detailed control over engraving.

Common Issues and How to Improve CNC Precision

Misalignment, tool wear, and machine vibrations can reduce precision. Regular maintenance, proper calibration, and high-quality cutting tools can mitigate these issues.

Techniques for CNC Wood Carving

Choosing the Right Wood for CNC Carving

Choose solid wood, plywood, or acrylic for your project. This choice helps with a smooth engraving process and high durability.

Tips for Beginners in CNC Woodworking

- Start with simple DIY projects to get familiar with CNC operations.

- Use high-quality CNC router machines designed for beginners.

- Test designs on scrap wood before working on final materials.

Carving Milling Techniques for Wood Art

Different milling techniques like deep, relief, and laser engraving provide various artistic results.

Laser Engraving vs. CNC Router Engraving

- Laser engraving offers sharper, burn-free edges.

- CNC router engraving provides deep carvings with better material removal.

Customization and Design Flexibility in CNC Projects

With CNC wood carving, users can create customized wall hanging designs, home décor items, and personalized gifts.

Best CNC Wood Carving Machines in 2024

The best CNC routers for hobbyists and professionals include:

- Next Wave Shark: Known for high precision.

- Pro CNC Machines: Ideal for professional woodworkers.

- DIY CNC Machines: Affordable and beginner-friendly options.

CNC Wood Carving for Different Applications

- Home décor and wall hanging projects.

- Small business opportunities in woodworking.

- Acrylic, plastic, and composite wood engraving.

- Professional woodworking projects with CNC precision.

Setting Up and Operating a CNC Wood Carving Machine

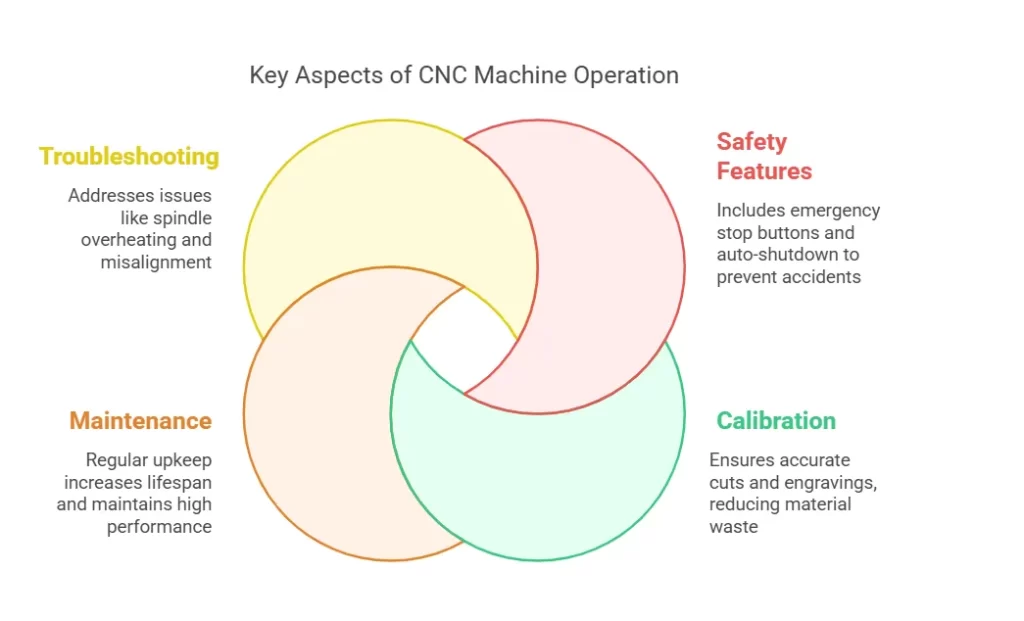

Essential Safety Features Like an Emergency Stop Button

Safety is crucial when operating CNC machines. Features like emergency stop buttons and auto-shutdown prevent accidents.

Machine Calibration and Work Area Setup

Proper calibration ensures accurate cuts and engravings, reducing material waste.

Maintenance and Durability of CNC Machines

Regular machine maintenance increases lifespan and maintains high performance.

Troubleshooting Common CNC Machine Issues

You can fix issues like spindle overheating, engraving mistakes, and misalignment. Just do regular checks and use the right settings.

Also Read: E-Galleries in Art: Impact on E Gallery & Wood Art Studio 2025

Future of CNC Wood Carving

Next-Level CNC Technologies in Woodworking

AI-powered CNC machines are changing wood carving. They bring smart automation and better design options.

Expanding CNC Woodworking Through Online Communities Like YouTube

YouTube and Amazon.com let hobbyists and pros share designs, tutorials, and CNC ideas.

CNC wood carving changes the game in woodworking. It provides high precision and efficiency. Plus, it opens up endless design possibilities. No matter if you’re a beginner, pro, or hobbyist, a good CNC machine can create new chances. You can use it for home décor, furniture making, and fun engraving projects.